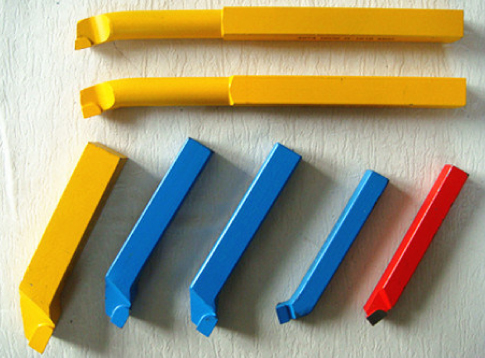

Tungsten Carbide Turning Tools as Per American Standards

| STRAIGHT TURNING TOOLS

AR & AL Style tools with 0° side cutting edge angle. |

|

AR Style

|

Shank Size |

Shank Dimension in inches |

R |

Tip Dimension in mm |

|||||

| A B C | ISO Tip | W | s | t | ||||

|

AR -4 |

1/4 |

1/4 |

2 |

1/64 |

A5 |

5 |

3 |

2 |

|

AR -5 |

5/16 |

5/16 |

2-1/4 |

1/64 |

A5 |

5 |

3 |

2 |

|

AR -6 |

3/8 |

3/8 |

2-1/2 |

1/64 |

A6 |

6 |

4 |

2.5 |

|

AR -7 |

7/16 |

7/16 |

3 |

1/32 |

A8 |

8 |

5 |

3 |

|

AR -8 |

1/2 |

1/2 |

3-1/2 |

1/32 |

A10 |

10 |

6 |

4 |

|

AR -10 |

5/8 |

5/8 |

4 |

1/32 |

A12 |

12 |

8 |

5 |

|

AR -12 |

3/4 |

3/4 |

4-1/2 |

1/32 |

A16 |

16 |

10 |

6 |

|

AR -16 |

1 |

1 |

7 |

1/32 |

A20 |

20 |

12 |

7 |

|

AR -20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

A25 |

25 |

14 |

8 |

|

AR -24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

A25 |

25 |

14 |

8 |

|

AR -44 |

1/2 |

1 |

7 |

1/32 |

A10 |

10 |

6 |

4 |

|

AR-54 |

5/8 |

1 |

6 |

1/32 |

A12 |

12 |

8 |

5 |

|

AR-55 |

5/8 |

1-1/4 |

8 |

1/32 |

A12 |

12 |

8 |

5 |

|

AR -64 |

3/4 |

1 |

6 |

1/32 |

A16 |

16 |

10 |

6 |

|

AR-66 |

3/4 |

1-1/2 |

8 |

1/32 |

A16 |

16 |

10 |

6 |

|

AR-85 |

1 |

1-1/4 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

|

AR-86 |

1 |

1-1/2 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

AL Style

|

Shank Size |

Shank Dimension in inches |

R |

Tip Dimension in mm |

|||||

| A B C | ISO Tip | W | s | t | ||||

|

AL-4 |

1/4 |

1/4 |

2 |

1/64 |

B5 |

5 |

3 |

2 |

|

AL-5 |

5/16 |

5/16 |

2-1/4 |

1/64 |

B5 |

5 |

3 |

2 |

|

AL-6 |

3/8 |

3/8 |

2-1/2 |

1/64 |

B6 |

6 |

4 |

2.5 |

|

AL-7 |

7/16 |

7/16 |

3 |

1/32 |

B8 |

8 |

5 |

3 |

|

AL-8 |

1/2 |

1/2 |

3-1/2 |

1/32 |

B10 |

10 |

6 |

4 |

|

AL-10 |

5/8 |

5/8 |

4 |

1/32 |

B12 |

12 |

8 |

5 |

|

AL-12 |

3/4 |

3/4 |

4-1/2 |

1/32 |

B16 |

16 |

10 |

6 |

|

AL-16 |

1 |

1 |

7 |

1/32 |

B20 |

20 |

12 |

7 |

|

AL-20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

B25 |

25 |

14 |

8 |

|

AL-24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

B25 |

25 |

14 |

8 |

|

AL-44 |

1/2 |

1 |

7 |

1/32 |

B10 |

10 |

6 |

4 |

|

AL-54 |

5/8 |

1 |

6 |

1/32 |

B12 |

12 |

8 |

5 |

|

AL-55 |

5/8 |

1-1/4 |

8 |

1/32 |

B12 |

12 |

8 |

5 |

|

AL -64 |

3/4 |

1 |

6 |

1/32 |

B16 |

16 |

10 |

6 |

|

AL-66 |

3/4 |

1-1/2 |

8 |

1/32 |

B16 |

16 |

10 |

6 |

|

AL-85 |

1 |

1-1/4 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

|

AL-86 |

1 |

1-1/2 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

| LEAD ANGLE TURNING TOOLS

BR & BL Style tools. |

|

BR Style

|

Shank Size |

Shank Dimension in inches |

R |

Tip Dimension in mm |

|||||

| A B C | ISO Tip | W | s | t | ||||

|

BR -4 |

1/4 |

1/4 |

2 |

1/64 |

A5 |

5 |

3 |

2 |

|

BR -5 |

5/16 |

5/16 |

2-1/4 |

1/64 |

A5 |

5 |

3 |

2 |

|

BR -6 |

3/8 |

3/8 |

2-1/2 |

1/64 |

A6 |

6 |

4 |

2.5 |

|

BR -7 |

7/16 |

7/16 |

3 |

1/32 |

A8 |

8 |

5 |

3 |

|

BR -8 |

1/2 |

1/2 |

3-1/2 |

1/32 |

A10 |

10 |

6 |

4 |

|

BR -10 |

5/8 |

5/8 |

4 |

1/32 |

A12 |

12 |

8 |

5 |

|

BR -12 |

3/4 |

3/4 |

4-1/2 |

1/32 |

A16 |

16 |

10 |

6 |

|

BR -16 |

1 |

1 |

7 |

1/32 |

A20 |

20 |

12 |

7 |

|

BR -20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

A25 |

25 |

14 |

8 |

|

BR -24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

A25 |

25 |

14 |

8 |

|

BR -44 |

1/2 |

1 |

7 |

1/32 |

A10 |

25 |

14 |

8 |

|

BR-54 |

5/8 |

1 |

6 |

1/32 |

A12 |

12 |

8 |

5 |

|

BR-55 |

5/8 |

1-1/4 |

8 |

1/32 |

A12 |

12 |

8 |

5 |

|

BR -64 |

3/4 |

1 |

6 |

1/32 |

A16 |

16 |

10 |

6 |

|

BR-66 |

3/4 |

1-1/2 |

8 |

1/32 |

A16 |

16 |

10 |

6 |

|

BR-85 |

1 |

1-1/4 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

|

BR-86 |

1 |

1-1/2 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

BL Style

|

Shank Size |

Shank Dimension in inches |

R |

Tip Dimension in mm |

|||||

| A B C | ISO Tip | W | s | t | ||||

|

BL-4 |

1/4 |

1/4 |

2 |

1/64 |

B5 |

5 |

3 |

2 |

|

BL-5 |

5/16 |

5/16 |

2-1/4 |

1/64 |

B5 |

5 |

3 |

2 |

|

BL-6 |

3/8 |

3/8 |

2-1/2 |

1/64 |

B6 |

6 |

4 |

2.5 |

|

BL-7 |

7/16 |

7/16 |

3 |

1/32 |

B8 |

8 |

5 |

3 |

|

BL-8 |

1/2 |

1/2 |

3-1/2 |

1/32 |

B10 |

10 |

6 |

4 |

|

BL-10 |

5/8 |

5/8 |

4 |

1/32 |

B12 |

12 |

8 |

5 |

|

BL-12 |

3/4 |

3/4 |

4-1/2 |

1/32 |

B16 |

16 |

10 |

6 |

|

BL-16 |

1 |

1 |

7 |

1/32 |

B20 |

20 |

12 |

7 |

|

BL-20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

B25 |

25 |

14 |

8 |

|

BL-24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

B25 |

25 |

14 |

8 |

|

BL-44 |

1/2 |

1 |

7 |

1/32 |

B10 |

10 |

6 |

4 |

|

BL-54 |

5/8 |

1 |

6 |

1/32 |

B12 |

12 |

8 |

5 |

|

BL-55 |

5/8 |

1-1/4 |

8 |

1/32 |

B12 |

12 |

8 |

5 |

|

BL -64 |

3/4 |

1 |

6 |

1/32 |

B16 |

16 |

10 |

6 |

|

BL-66 |

3/4 |

1-1/2 |

8 |

1/32 |

B16 |

16 |

10 |

6 |

|

BL-85 |

1 |

1-1/4 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

|

BL-86 |

1 |

1-1/2 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

| SQUARE NOSE TOOL

C Style tools 0° Square Nose.

|

|

C Style

|

Shank Size |

Shank Dimension in inches |

Tip Dimension in mm |

|||||

|

A B C |

ISO Tip |

W |

s |

t |

|||

|

C -4 |

¼ |

¼ |

2 |

C6 |

6 |

4 |

2.5 |

|

C -5 |

5/16 |

5/16 |

2-1/4 |

C8 |

8 |

5 |

3 |

|

C -6 |

3/8 |

3/8 |

2-1/2 |

C10 |

10 |

6 |

4 |

|

C -7 |

7/16 |

7/16 |

3 |

C10 |

10 |

6 |

4 |

|

C -8 |

½ |

½ |

3-1/2 |

C12 |

12 |

8 |

5 |

|

C-10 |

5/8 |

5/8 |

4 |

C16 |

16 |

10 |

6 |

|

C-12 |

¾ |

3/4 |

4-1/2 |

C20 |

20 |

12 |

7 |

|

C-16 |

1 |

1 |

7 |

C25 |

25 |

14 |

8 |

|

C-20 |

1-1/4 |

1-1/4 |

8 |

C32 |

32 |

18 |

10 |

|

C-44 |

½ |

1 |

7 |

C12 |

12 |

8 |

5 |

|

C-54 |

5/8 |

1 |

6 |

C16 |

16 |

10 |

6 |

|

C-55 |

5/8 |

1-1/4 |

8 |

C16 |

16 |

10 |

6 |

|

C-64 |

¾ |

1 |

6 |

C20 |

20 |

12 |

7 |

|

C-66 |

¾ |

1-1/2 |

8 |

C20 |

20 |

12 |

7 |

|

C-86 |

1 |

1-1/2 |

8 |

C25 |

25 |

14 |

8 |

| CUT OFF TOOLS

CTR & CTL Style. |

|

CTR & CTL

|

Shank Size |

Shank Dimension in inches |

Tip Dimension in mm |

|||||||

| A B C D W |

ISO Tip |

W |

s |

t |

|||||

|

CTR-111 |

½ |

1 |

5 |

3/4 |

1/8 |

D3 |

3 |

8 |

3 |

|

CTR-122 |

½ |

1 |

5 |

3/16 |

3/16 |

D5 |

5 |

12 |

5 |

|

CTR-120 |

½ |

1 |

5 |

1 |

5/16 |

D8 |

8 |

16 |

8 |

|

CTR-121 |

½ |

1 |

5 |

1 |

1/4 |

D6 |

6 |

14 |

6 |

|

CTR-130 |

5/8 |

1-1/4 |

5 |

1-1/4 |

3/8 |

D10 |

10 |

18 |

10 |

|

CTR-140 |

¾ |

1-1/2 |

6 |

1-1/4 |

3/8 |

D10 |

10 |

18 |

10 |

|

CTL-111 |

½ |

1 |

5 |

3/4 |

1/8 |

D3 |

3 |

8 |

3 |

|

CTL-122 |

½ |

1 |

5 |

3/16 |

3/16 |

D5 |

5 |

12 |

5 |

|

CTL-120 |

½ |

1 |

5 |

1 |

5/16 |

D8 |

8 |

16 |

8 |

|

CTL-121 |

½ |

1 |

5 |

1 |

1/4 |

D6 |

6 |

14 |

6 |

|

CTL-130 |

5/8 |

1-1/4 |

5 |

1-1/4 |

3/8 |

D10 |

10 |

18 |

10 |

|

CTL-140 |

¾ |

1-1/2 |

6 |

1-1/4 |

3/8 |

D10 |

10 |

18 |

10 |

| POINTED NOSE TOOL

D Style tools with 80° included Angle. . |

|

D Style

|

Shank Size |

Shank Dimension in inches |

R |

Tip Dimension in mm |

|||||

| A B C | ASA Tip |

w |

s |

t |

||||

|

D -4 |

1/4 |

1/4 |

2 |

1/64 |

5030 |

6.4 |

7.9 |

1.6 |

|

D -5 |

5/16 |

5/16 |

2-1/4 |

1/64 |

5080 |

7.9 |

9.5 |

2.4 |

|

D -6 |

3/8 |

3/8 |

2-1/2 |

1/64 |

5100 |

9.5 |

12.7 |

2.4 |

|

D -7 |

7/16 |

7/16 |

3 |

1/32 |

5105 |

11.1 |

12.7 |

2.4 |

|

D -8 |

1/2 |

1/2 |

3-1/2 |

1/32 |

5200 |

12.7 |

12.7 |

3.2 |

|

D-10 |

5/8 |

5/8 |

4 |

1/32 |

5240 |

15.9 |

115.9 |

4.0 |

|

D-12 |

3/4 |

3/4 |

4-1/2 |

1/32 |

5340 |

19.1 |

19.1 |

4.8 |

|

D-16 |

1 |

1 |

7 |

1/32 |

5410 |

25.4 |

19.1 |

6.4 |

| THREADING TOOL

E Style TOOL-60° Include Angle. |

|

E Style

|

Shank Size |

Shank Dimension in inches |

Tip Dimension |

|||||

| A B C |

ASA Tip |

w | s | t | |||

|

E-5 |

5/16 |

5/16 |

2-1/4 |

6080 |

7.9 |

9.5 |

2.4 |

|

E-6 |

3/8 |

3/8 |

2-1/2 |

6100 |

9.5 |

12.7 |

2.4 |

|

E-7 |

7/16 |

7/16 |

3 |

6105 |

11.1 |

12.7 |

2.4 |

|

E-8 |

½ |

1/2 |

3-1/2 |

6200 |

12.7 |

12.7 |

3.2 |

|

E-10 |

5/8 |

5/8 |

4 |

6240 |

15.9 |

15.9 |

4.0 |

|

E-12 |

¾ |

3/4 |

4-1/2 |

6340 |

19.1 |

19.1 |

4.8 |

| OFFSET THREADING TOOL

ER & EL Style Tool. |

|

ER Style

|

Shank Size |

Shank Dimension in inches |

Tip Dimension |

||||||

| A B C F |

UF Tip |

W | s | t | ||||

|

ER-4 |

¼ |

1/4 |

2 |

1/16 |

UF12 |

12 |

4 |

3 |

|

ER-5 |

5/16 |

5/16 |

2-1/4 |

1/16 |

UF12 |

12 |

4 |

3 |

|

ER-6 |

3/8 |

3/8 |

2-1/2 |

1/16 |

UF12 |

12 |

4 |

3 |

|

ER-8 |

½ |

1/2 |

3-1/2 |

3/32 |

UF14 |

14 |

4 |

4 |

|

ER-10 |

5/8 |

5/8 |

4 |

3/32 |

UF16 |

16 |

5 |

5 |

|

ER-12 |

¾ |

3/4 |

4-1/2 |

1/8 |

UF20 |

20 |

7 |

6 |

EL Style

|

Shank Size |

Shank Dimension in inches |

Tip Dimension |

||||||

| A B C F |

UF Tip |

w | s | t | ||||

|

EL-4 |

¼ |

1/4 |

2 |

1/16 |

UF12 |

12 |

4 |

3 |

|

EL-5 |

5/16 |

5/16 |

2-1/4 |

1/16 |

UF12 |

12 |

4 |

3 |

|

EL-6 |

3/8 |

3/8 |

2-1/2 |

1/16 |

UF12 |

12 |

4 |

3 |

|

EL-8 |

½ |

1/2 |

3-1/2 |

3/32 |

UF14 |

14 |

4 |

4 |

|

EL-10 |

5/8 |

5/8 |

4 |

3/32 |

UF16 |

16 |

5 |

5 |

|

EL-12 |

¾ |

3/4 |

4-1/2 |

1/8 |

UF20 |

20 |

7 |

6 |

| END CUTTING OFFSET TOOLS

FR Style Tools- 0° end cutting edge angle. |

|

FR Style

|

Shank Size |

Shank Dimension in inches |

Nose

Radius |

Tip Dimension |

|||||

| A B C |

ISO Tip |

W | s | t | ||||

|

FR-8 |

½ |

1/2 |

3-1/2 |

1/32 |

B10 |

10 |

6 |

4 |

|

FR-10 |

5/8 |

5/8 |

4 |

1/32 |

B12 |

12 |

8 |

5 |

|

FR-12 |

¾ |

3/4 |

4-1/2 |

1/32 |

B16 |

16 |

10 |

6 |

|

FR-16 |

1 |

1 |

7 |

1/32 |

B20 |

20 |

12 |

7 |

|

FR-20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

B25 |

25 |

14 |

8 |

|

FR-24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

B25 |

25 |

14 |

8 |

|

FR-44 |

½ |

1 |

6 |

1/32 |

B10 |

10 |

6 |

4 |

|

FR-55 |

5/8 |

1-1/4 |

7 |

1/32 |

B12 |

12 |

8 |

5 |

|

FR-64 |

¾ |

1 |

6 |

1/32 |

B16 |

16 |

10 |

6 |

|

FR-66 |

¾ |

1-1/2 |

8 |

1/32 |

B16 |

16 |

10 |

6 |

|

FR-85 |

1 |

1-1/4 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

|

FR-86 |

1 |

1-1/2 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

FL Style

|

Shank Size |

Shank Dimension in inches |

Nose

Radius |

Tip Dimension |

|||||

| A B C |

ISO Tip |

W | s | t | ||||

|

FL-8 |

½ |

1/2 |

3-1/2 |

1/32 |

A10 |

10 |

6 |

4 |

|

FL-10 |

5/8 |

5/8 |

4 |

1/32 |

A12 |

12 |

8 |

5 |

|

FL-12 |

¾ |

3/4 |

4-1/2 |

1/32 |

A16 |

16 |

10 |

6 |

|

FL-16 |

1 |

1 |

7 |

1/32 |

A20 |

20 |

12 |

7 |

|

FL-20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

A25 |

25 |

14 |

8 |

|

FL-24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

A25 |

25 |

14 |

8 |

|

FL-44 |

1/2 |

1 |

6 |

1/32 |

A10 |

10 |

6 |

4 |

|

FL-55 |

5/8 |

1-1/4 |

7 |

1/32 |

A12 |

12 |

8 |

5 |

|

FL-64 |

3/4 |

1 |

6 |

1/32 |

A16 |

16 |

10 |

6 |

|

FL-66 |

3/4 |

1-1/2 |

8 |

1/32 |

A16 |

16 |

10 |

6 |

|

FL-85 |

1 |

1-1/4 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

|

FL-86 |

1 |

1-1/2 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

| SIDE CUTTING OFFSET TOOLS

GR Style Tools- 0° end cutting edge angle. |

|

GR Style

|

Shank Size |

Shank Dimension in inches |

Nose

Radius |

Tip Dimension |

|||||

| A B C |

ISO Tip |

W |

s |

t |

||||

|

GR-8 |

1/2 |

1/2 |

3-1/2 |

1/32 |

A10 |

10 |

6 |

4 |

|

GR-10 |

5/8 |

5/8 |

4 |

1/32 |

A12 |

12 |

8 |

5 |

|

GR-12 |

3/4 |

3/4 |

4-1/2 |

1/32 |

A16 |

16 |

10 |

6 |

|

GR-16 |

1 |

1 |

7 |

1/32 |

A20 |

20 |

12 |

7 |

|

GR-20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

A25 |

25 |

14 |

8 |

|

GR-24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

A25 |

25 |

14 |

8 |

|

GR-44 |

1/2 |

1 |

6 |

1/32 |

A10 |

10 |

6 |

4 |

|

GR-55 |

5/8 |

1-1/4 |

7 |

1/32 |

A12 |

12 |

8 |

5 |

|

GR-64 |

3/4 |

1 |

6 |

1/32 |

A16 |

16 |

10 |

6 |

|

GR-66 |

3/4 |

1-1/2 |

8 |

1/32 |

A16 |

16 |

10 |

6 |

|

GR-85 |

1 |

1-1/4 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

|

GR-86 |

1 |

1-1/2 |

8 |

1/32 |

A20 |

20 |

12 |

7 |

GL Style

|

Shank Size |

Shank Dimension in inches |

Nose

Radius |

Tip Dimension |

|||||

| A B C |

ISO Tip |

W |

s |

t |

||||

|

GL-8 |

1/2 |

1/2 |

3-1/2 |

1/32 |

B10 |

10 |

6 |

4 |

|

GL-10 |

5/8 |

5/8 |

4 |

1/32 |

B12 |

12 |

8 |

5 |

|

GL-12 |

3/4 |

3/4 |

4-1/2 |

1/32 |

B16 |

16 |

10 |

6 |

|

GL-16 |

1 |

1 |

7 |

1/32 |

B20 |

20 |

12 |

7 |

|

G-20 |

1-1/4 |

1-1/4 |

8 |

1/32 |

B25 |

25 |

14 |

8 |

|

GL-24 |

1-1/2 |

1-1/2 |

8 |

1/16 |

B25 |

25 |

14 |

8 |

|

GL-44 |

1/2 |

1 |

6 |

1/32 |

B10 |

10 |

6 |

4 |

|

GL-55 |

5/8 |

1-1/4 |

7 |

1/32 |

B12 |

12 |

8 |

5 |

|

GL-64 |

3/4 |

1 |

6 |

1/32 |

B16 |

16 |

10 |

6 |

|

GL-66 |

3/4 |

1-1/2 |

8 |

1/32 |

B16 |

16 |

10 |

6 |

|

GL-85 |

1 |

1-1/4 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

|

GL-86 |

1 |

1-1/2 |

8 |

1/32 |

B20 |

20 |

12 |

7 |

| SQUARE SHANK BORING TOOLS

SA Style – For Boring to square shoulder in a 90° boring bar. High positive rake. |

|

SA – SC – SE

|

Shank Size |

Shank Dimension in inches |

Nose Radius |

Tip Dimension in mm |

|||||

| A B C |

ISO Tip |

W |

s |

t |

||||

|

SA-4 |

1/4 |

1/4 |

1-1/2 |

1/64 |

B5 |

5 |

3 |

2 |

|

SA-5 |

5/16 |

5/16 |

1-1/2 |

1/64 |

B6 |

6 |

4 |

2.5 |

|

SA-6 |

3/8 |

3/8 |

1-3/4 |

1/64 |

B8 |

8 |

5 |

3 |

|

SA-8 |

1/2 |

1/2 |

2-1/2 |

1/32 |

B10 |

10 |

6 |

4 |

|

SA-10 |

5/8 |

5/8 |

3 |

1/32 |

B12 |

12 |

8 |

5 |

|

SA-12 |

3/4 |

3/4 |

3-1/2 |

1/32 |

B16 |

16 |

10 |

6 |

|

SB-4 |

1/4 |

1/4 |

1-1/2 |

1/64 |

A5 |

5 |

3 |

2 |

|

SB-5 |

5/16 |

5/16 |

1-1/2 |

1/64 |

A6 |

6 |

4 |

2.5 |

|

SB-6 |

3/8 |

3/8 |

1-3/4 |

1/64 |

A8 |

8 |

5 |

3 |

|

SB-8 |

1/2 |

1/2 |

2-1/2 |

1/32 |

A10 |

10 |

6 |

4 |

|

SB-10 |

5/8 |

5/8 |

3 |

1/32 |

A12 |

12 |

8 |

5 |

|

SB-12 |

3/4 |

3/4 |

3-1/2 |

1/32 |

A16 |

16 |

10 |

6 |

|

SC-4 |

1/4 |

1/4 |

1-1/2 |

1/64 |

B5 |

5 |

3 |

2 |

|

SC-5 |

5/16 |

5/16 |

1-1/2 |

1/64 |

B6 |

6 |

4 |

2.5 |

|

SC-6 |

3/8 |

3/8 |

1-3/4 |

1/64 |

B8 |

8 |

5 |

3 |

|

SC-8 |

1/2 |

1/2 |

2-1/2 |

1/32 |

B10 |

10 |

6 |

4 |

|

SC-10 |

5/8 |

5/8 |

3 |

1/32 |

B12 |

12 |

8 |

5 |

|

SC-12 |

3/4 |

3/4 |

3-1/2 |

1/32 |

B16 |

16 |

10 |

6 |

|

SD-4 |

1/4 |

1/4 |

1-1/2 |

1/64 |

A5 |

5 |

3 |

2 |

|

SD-5 |

5/16 |

5/16 |

1-1/2 |

1/64 |

A6 |

6 |

4 |

2.5 |

|

SD-6 |

3/8 |

3/8 |

1-3/4 |

1/64 |

A8 |

8 |

5 |

3 |

|

SD-8 |

1/2 |

1/2 |

2-1/2 |

1/32 |

A10 |

10 |

6 |

4 |

|

SD-10 |

5/8 |

5/8 |

3 |

1/32 |

A12 |

12 |

8 |

5 |

|

SD-12 |

3/4 |

3/4 |

3-1/2 |

1/32 |

A16 |

16 |

10 |

6 |

|

SE-4 |

1/4 |

1/4 |

1-1/2 |

1/64 |

B5 |

5 |

3 |

2 |

|

SE-5 |

5/16 |

5/16 |

1-1/2 |

1/64 |

B6 |

6 |

4 |

2.5 |

|

SE-6 |

3/8 |

3/8 |

1-3/4 |

1/64 |

B8 |

8 |

5 |

3 |

|

SE-8 |

1/2 |

1/2 |

2-1/2 |

1/32 |

B10 |

10 |

6 |

4 |

|

SE-10 |

5/8 |

5/8 |

3 |

1/32 |

B12 |

12 |

8 |

5 |

|

SE-12 |

3/4 |

3/4 |

3-1/2 |

1/32 |

B16 |

16 |

10 |

6 |

|

SF-4 |

1/4 |

1/4 |

1-1/2 |

1/64 |

A5 |

5 |

3 |

2 |

|

SF-5 |

5/16 |

5/16 |

1-1/2 |

1/64 |

A6 |

6 |

4 |

2.5 |

|

SF-6 |

3/8 |

3/8 |

1-3/4 |

1/64 |

A8 |

8 |

5 |

3 |

|

SF-8 |

1/2 |

1/2 |

2-1/2 |

1/32 |

A10 |

10 |

6 |

4 |

|

SF-10 |

5/8 |

5/8 |

3 |

1/32 |

A12 |

12 |

8 |

5 |

|

SF-12 |

3/4 |

3/4 |

3-1/2 |

1/32 |

A16 |

16 |

10 |

6 |